News

How We Ensure Safe Domestic Water Conditions in a Healthcare Environment

How We Ensure Safe Domestic Water Conditions in a Healthcare Environment

Within healthcare environments, ensuring safe domestic water conditions is critical. While all buildings should operate safely and efficiently to protect those using or residing in them, healthcare facilities require attention due to the vulnerable populations they serve.

One significant risk is the proliferation of Legionella bacteria, which can occur in both hot and cold water systems. Legionella can cause Legionnaires’ disease, a serious lung infection that poses a heightened threat in healthcare settings, particularly to vulnerable groups such as the elderly, the immunocompromised, and those with underlying health conditions. For these individuals, exposure to contaminated water can lead to serious infection or illness.

To mitigate these risks, it is crucial to maintain safe and compliant temperatures in both hot and cold-water systems. However, ensuring the safety of cold water systems require special attention, as cold water temperatures must be kept below certain thresholds to prevent the growth of Legionella. In all healthcare buildings, maintaining safe cold water temperatures is essential to safeguard both patients and staff from waterborne hazards.

Regulatory Frameworks

In England, Wales, and Northern Ireland, healthcare facilities adhere to the guidelines outlined in HTM 04-01, while Scotland follows SHTM 04-01, and Ireland has its own set of water safety standards. Both HTM 04-01 and SHTM 04-01 provide comprehensive guidance on the design, installation, and testing of water systems in healthcare settings.

According to SHTM 04-01 Part A: Design, Installation, and Testing, cold water systems should deliver water at temperatures below 20°C under normal circumstances. This is crucial because Legionella bacteria thrive in temperatures between 20°C and 45°C, making it vital to maintain cold water temperatures below this threshold to minimise the risk of contamination.

Challenges in Ensuring Safe Water Conditions

Several factors contribute to heat gain in cold water systems, making it challenging to maintain safe temperatures. Some of the key factors include:

- Lack of turnover in the cold water system – This can occur due to oversized cold water storage tanks or infrequent use of appliances, leading to stagnant water and increased risk of temperature rise.

- Incoming mains cold water temperature – Depending on location and the type of mains supply, the temperature of incoming cold water may be beyond the user’s control. This lack of control can result in passive heat gain, increasing the risk of Legionella proliferation.

- Internal ceiling void temperatures – With modern buildings designed to meet stringent energy efficiency standards, minimal heat is lost from the building. However, this can inadvertently cause elevated ceiling void temperatures, where cold water distribution systems are often located, leading to heat gain within the pipes.

Mitigation Strategies

Mitigation strategies are critical in healthcare design and construction as they help identify, address, and reduce risks that could compromise the safety of both the facility and its patients. By implementing these strategies, healthcare facilities can better maintain safe water conditions and minimise the risk of contamination.

Several passive solutions are available to help mitigate temperature gain within cold water systems, including:

- Reducing cold water storage volumes – This increases water turnover within the system, ensuring fresher water and reducing the chances of heat gain.

- Separating cold water distribution from heat sources – Where possible, keep cold water pipes and systems as far away from heat-emitting equipment and spaces to minimise passive heat transfer.

- Promoting system turnover – Ensure that a regularly used appliance is positioned at the end of the cold water system. This will encourage consistent water flow throughout the system, reducing stagnation and the risk of temperature rise.

While these passive methods can help mitigate heat gain, they do not guarantee that cold water temperatures will consistently remain at safe levels. As a result, we can also incorporate mechanical solutions into our systems.

However, it’s important to note that there is generally no specific guidance for cooling cold water systems or adding a cold water return system, as this is still a relatively new approach. There are multiple ways to achieve this, and each method must be implemented carefully to avoid introducing additional risks. It is also essential to ensure that the client is fully informed throughout the process, as the chosen mechanical mitigation strategy should align with the specific needs and context of the healthcare facility.

Mechanical Mitigation: Cold Water Circulation Systems

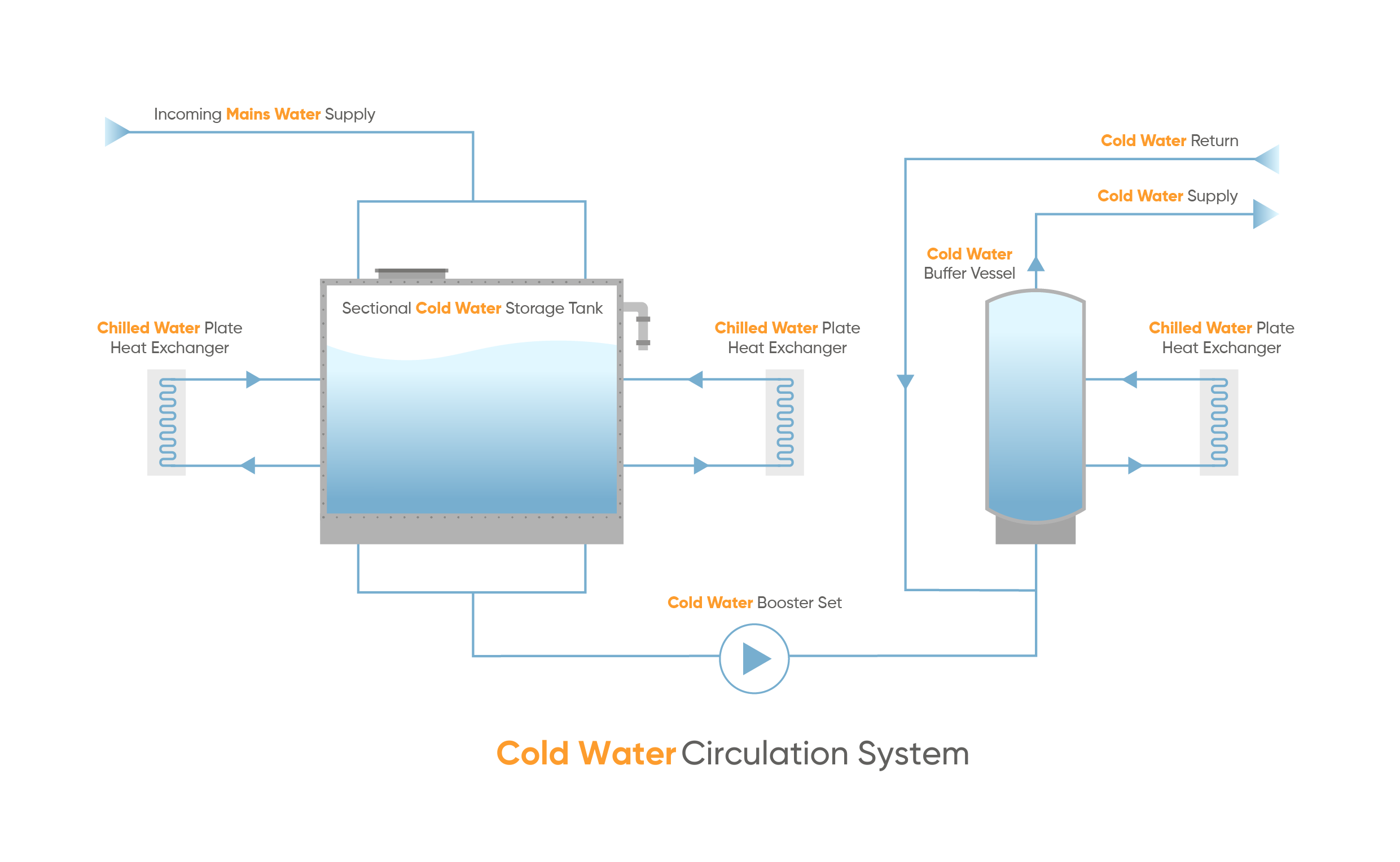

One of the most effective systems used within healthcare facilities is the cold water return system, which functions similarly to a traditional hot water circulation system. In this system, the return pipes are positioned as close as possible to the cold water appliances to minimise dead legs, where stagnant water could accumulate.

The cold water is continuously circulated back to a buffer vessel, which is equipped with a cooling plate heat exchanger. This system ensures that the water maintains a safe, compliant temperature, while also promoting constant movement, which helps to mitigate the risk of stagnation—a key factor in preventing the growth of Legionella bacteria.

To optimise the system, thermal balancing valves are installed on each return branch. These valves open when they detect higher water temperatures, allowing colder water to circulate through the system. This ensures that all return legs are properly circulating water at the desired temperature.

As well as cooling the cold water return system we also introduce a cooling plate heat exchanger to the cold water storage tank. During times of little draw off the stored cold water is circulated via the cooling plate heat exchanger to ensure the water is stored at a compliant temperature.

By effectively controlling the delivered water temperature, the system guarantees safe and compliant water delivery to all appliances, ensuring both regulatory compliance and patient comfort.

Why Wallace Whittle?

At Wallace Whittle, we are dedicated partners committed to the success of every project. Our proactive approach to early communication and coordination ensures that safe domestic water conditions remain a top priority throughout the design process. This commitment not only enhances the functionality and efficiency of our designs but also contributes to creating safer environments for patients and staff.

Our extensive portfolio includes a range of successful projects across various regions and healthcare trusts. We have experience with different types of facilities, from acute care and day surgeries to outpatient care and community care centers. Some of our notable projects include the Clydebank Health & Care Centre, award-winning Eastwood Health and Care Centre, Greenock Health & Care Centre and Gorbals Health & Care Centre. These projects highlight our capability in delivering high-quality, functional, and compliant healthcare environments.

We are currently working on the Monklands Replacement Project, where our design proposals have been supported at the Outline Business Case (OBC) Key Stage Assurance Reviews (KSAR). This successful milestone underscores our commitment to meeting rigorous standards and delivering projects that meet both current and future needs.

Our team comprises dedicated engineers who excel in both Technical Advisory and Full Design Roles. We specialise in providing a complete package of Building Services and Sustainability design tailored to various healthcare settings. Whether for large-scale facilities or smaller community health and care centers, our expertise ensures optimal functionality and efficiency, with a strong focus on maintaining safe water conditions.

We’re excited to be attending the IHEEM 2024 Healthcare Estates Conference & Exhibition in Manchester! Visit us at Stand H8 to discuss our latest innovations and explore how we can support your healthcare projects. If you’d like to schedule a meeting over coffee or a drink, please feel free to contact our team directly.

If you’d like to discuss your next Healthcare project with us email [email protected] or to find out more, visit our dedicated healthcare site – Healthcare Expertise – Wallace Whittle

Niall Campbell

Principal Public Health Engineer